Salina Regional Course Offerings

Course Information for 2026

Green Belt

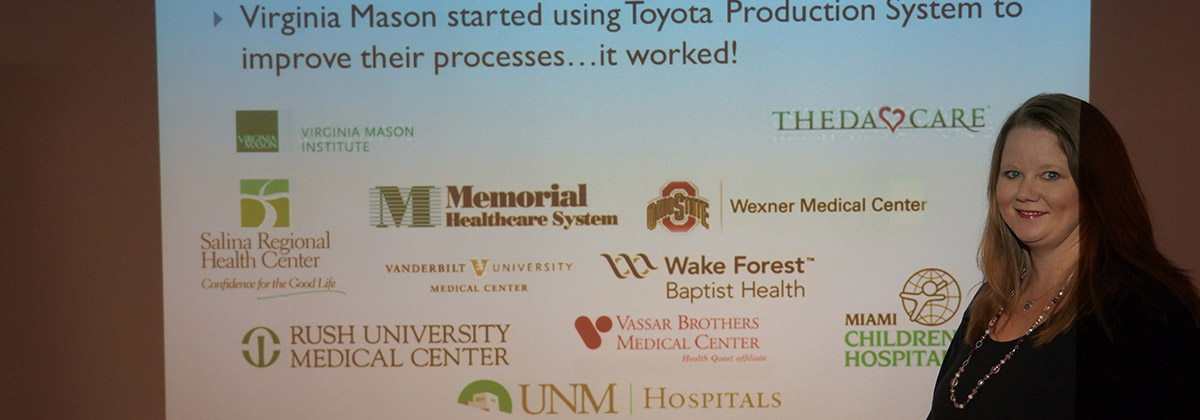

SRHC's Lean Academy Lean Six Sigma Green Belt course has been designed to teach Lean Six Sigma (LSS) fundamentals and its application. It is intended for part time improvement team project leaders. Students are trained and tested on their understanding and ability to apply the tools and techniques of all elements of the LSS methodology. As part of the SRHC's Production System (SRPS) methodology, students are taught how to integrate Lean Six Sigma into an overall approach to process improvement and project management.

Training is conducted using face-to-face format that includes examples of successful performance improvement, interactive simulations, and the most current and robust tools and techniques available. On average, students complete the Lean Six Sigma Green Belt training course in 28 hours (average completion time, actual time may vary).

SRHC's Lean Academy Six Sigma Green Belt course is one of the most comprehensive in the world. We recommend this course to Project Leaders, Department Directors, Hospital Administrators, Improvement Team Leaders, and Emerging Leaders.

The curriculum for Green Belt (GB) is for approximately 30 hours of academic training plus (for certification) a completed project. This is approximately equivalent to similar GB courses offered by other organizations. In some companies, GBs are provided with their own copies of software for statistical analysis, project planning, flowcharting, etc. The SRHC Lean Academy does not require the GB to be proficient in the use of the software, but relies on Black Belts (BBs) and Master Black Belts (MBBs) for this service. GB training is extended to provide the necessary hands-on classroom experience using the software. The SRHC Lean Academy uses “Sigma Magic” as the lean statistics analysis software of choice due to ease of use, low cost, and indefinite license.

Curriculum

Other benefits to SRHC's GBs are the open offer for personal one-on-one coaching and mentoring by a highly experienced and certified Master Black Belt. Cost: $1500 per student

Location: Salina Regional Health Center

- Welcome and opening comments

- Lean 101 : The Case for Lean Healthcare

- Toast Kaizen Video

- Basic tools of Lean

- Brain storming

- Box Plots

- Histograms

- Data Collection Methods

- Force Field Analysis

- Affinity Diagram and Silent Affinity

- Pareto Diagram

- Check Sheets

- Concentration Diagrams

- A3 Thinking

- Go and See! The Gemba Walk

- Math Camp

- Basic entry level statistics (mean, median, Std Dev, etc.)

- Distributions

- Box Plots

- Confidence Intervals

- Sampling and Sample Size Computation

- Hypothesis testing for continuous data using the T-Test

- Analysis of Variance (ANOVA)

- Single and multiple regression

- Correlation Coefficients

- Process Capability for Continuous Data

- Cp, Cpk, Pp, Ppk, CpL, CpU

- Cp, Cpk, Pp, Ppk, CpL, CpU

- Intro to Voice of the Customer

- Interviewing

- Focus Groups

- Surveys

- Customer Roles and Segmentation

- Tree Diagrams

- Critical Customer Requirement (CCR) Selection

- Alphabet Soup Simulation

- Control Charts for Continuous Data

- Control Chart Theory and History

- Deming's Tampering

- Shewhart's Theory

- Run Charts

- X-Bar R Charts

- IM&R Charts

- Attribute Data Charting Overview

- Process Behavior (Common and Special/Assignable Cause Variation)

- Process Mapping

- SIPOC

- Flow Chart

- Swimlane

- Value Stream Mapping (Current State)

- Value Stream Mapping (Future State)

- Shingo Style Value Stream Maps

- Cause and Effect (C&E) and Failure Modes and Effects Analysis (FMEA)

- Fishbone (Ishikawa) Diagrams

- Cause and Effect Matrix

- Process Flow Improvement

- Constraint Identification Overview

- Intro to Cellular Design

- The Value of Cycle Time

- Process Cycle Time (PCT)

- Work in Process (WIP)

- Process Cycle Efficiency (PCE)

- Throughput and Exit Rates

- The Impact of Variation on PCT

- Intro to the Rapid Improvement Event (RIE)

- Queuing Theory and “Shapes” simulation

- Terms Used in Queuing Science

- Queue Stability

- Agner Krarup Erlang's Hypothesis

- Lindley's Hypothesis

- John Frank Charles Kingman's Hypothesis and Mathematical Approximation

- Process Constraint Identification

- Takt Rate Analysis and Exercise

- Time Traps and Constraints

- Process Flow Improvement

- Spaghetti Diagrams

- 8 Flows of Medicine

- The Time Study

- Process Balancing

- Replenishment Pull Systems (1 and 2 Bins Systems)

- 1 and 2 Bin Kanban

- ABC Materials Management

- Setup Reduction

- Internal

- External

- 5S

- 5S Simulation

- Doh! Spill Cleanup Simulation (Capstone Exercise)

- Mistake Proofing and Poka Yoke

- Innovation, Solution Generation and Selection

- First, Second, and Third Order Changes

- The 6 Phases of Innovation

- Generating and Organizing Ideas

- The Pilot

- Edward DeBono's Theory

- Brainstorm Boosters

- Nominal Group Technique

- The Pugh Selection Matrix

- The Benefit-Effort Matrix

- Process Control and Implementation Plans

- Control Planning Tools and Techniques

- Control Plans

- Standard Operating Procedures (SOPs)

- Cultural Issues

SRHC is also proud to offer on-site Lean in Healthcare consulting on a by-the-hour fee format. We can help you, so please contact us.